SATTLER PRO-TEX products always fulfil their tasks thanks to a wide variety of product features.

Our high-quality coated membranes are used for applications with the highest demands on functionality, reliability, durability and environmental responsibility.

Thanks to our expertise, our research background and our latest technology, we develop tailor-made solutions for specific requirements together with our customers.

Our membranes enable beautifully shaped structures. Their versatility makes them ideal to create impressive buildings with unique designs. These are sustainable, cost-effective structures that only require minimal use of materials and resources.

As a responsible manufacturer, our top priority is to produce high-quality coated fabrics by following the strictest health and environmental standards.

All PVC-coated membranes by SATTLER PRO-TEX are “made in Austria”. The weaving of the polyester base fabrics in addition to the coating and varnishing processes are carried out in-house. Many years of experience, continuous improvements and new developments, as well as the dedication and commitment of our employees to guarantee high-quality products – all these features result in added value to our fabrics. Our certified quality and environment management systems comply with the requirements of ISO 9001:2015 and ISO 14001:2015, and guarantee the highest quality of our products and services.

Polyester base fabric

Membranes constitute a structural part of the building in tensile architecture, as the fabric must absorb and transfer an essential part of the forces involved. The necessary tensile strength is given by the woven base fabric of the membrane. Over the years, yarns of high-strength polyester fibers have established as ideal base cloth for a huge variety of applications. PVC polyester fabrics are chosen for their excellent strength that allows absorbing impressive forces but also for their lightweight in comparison to similar building materials. At SATTLER PRO-TEX, we use yarns in various tear strengths depending on the membrane type.

Apart from the choice of suitable yarns, the woven base structure is also essential for defining the resistance of the fabric. The so called “setting”, the number of threads per centimeter, and the weave, the manner how the threads are crossed with each other, determine which forces the fabric can absorb.

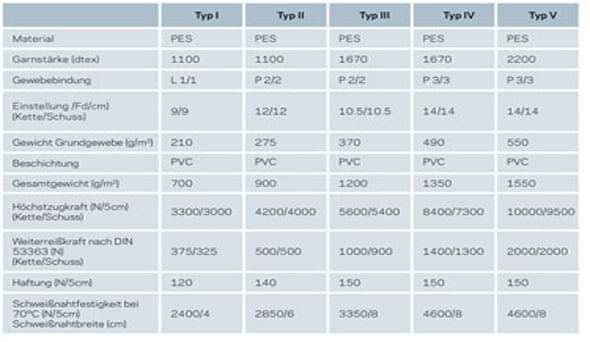

In tensile architecture, membranes are classified in so-called “types” according to certain tensile strength parameters. SATTLER PRO-TEX produces PVC-coated membranes ranging from Type I to Type V.

As the table shows, the five membrane types are distinguished by the yarn thickness, the type of weave and their weight after coating. Thus, the PVC-coated membranes differ in mechanical properties, such as maximum tensile strength and tear strength.

ATLAS - for more durability and sheen

The distinctive mark of the ATLAS membranes is the extra smooth surface of the fabric. The flat and even structure of the base fabric results in a coated membrane with a fantastic sheen and a very smooth surface.

The ATLAS membranes are whiter than conventional fabrics and have a beautiful shiny surface. The even surface of these high-quality fabrics ensures their elegant look and a homogeneous light transmission. The smooth surface hinders soiling, thus these fabrics are cleaner than conventional membranes.

BIAX characteristics

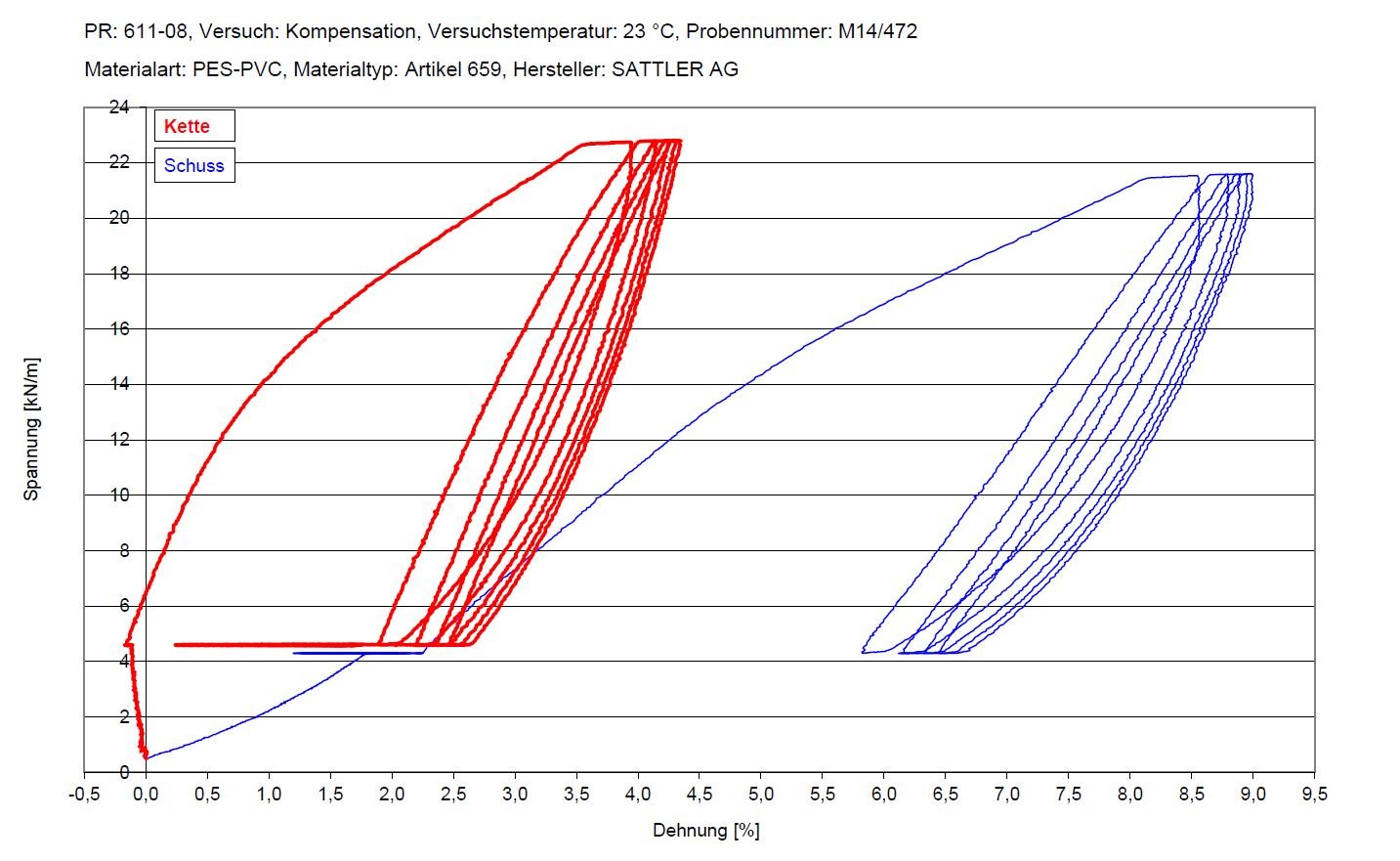

A feature of membranes for tensile architecture is their flexibility, which enables a unique range of three dimensional buildings. To calculate the pre-tension, basic parameters such as the definable stretching behavior under load and the recovery after relaxation are used.

From the huge variety of support fabrics, such as non-woven fabrics or knit fabrics, coated textiles have the most suitable basic prerequisites. A textile fabric is produced by crossing at least two threads in a right angle. Threads in longitudinal direction are called warp threads and those in cross direction weft threads. This results in two axes, which have to be considered when it comes to evaluating the stretching behavior of the membrane.

In order to provide the necessary flexibility, the threads of the membrane are not entirely tensioned and can be stretched further. The stretching and relaxation behavior have to be definable and calculable. This is achieved with so-called biaxial tests: By means of compensation tests, it is possible to simulate the load (caused by snow or wind) over the lifespan of the membrane.

Given its textile core, a membrane cannot return to its original size after experiencing a heavy load, but stretches out instead. For this reasons, tensile structures are manufactured undersize so that when installed to their final dimensions they tension out correctly.

The stretching behavior is irreversible to a certain degree. Biaxial tests allow an esteem of the pre-tension needed so that the membrane still has enough tension left for secure loading at the end of its lifetime.

This data serves as the basis to evaluate the shape of the building and carry out static calculation with corresponding computer software. Tensile membranes with higher flexibility need less pre-tension in comparison to pre-stressed fabrics, allow uniform load distribution within the construction and simplify manufacturing.

We are pleased to share these parameters with you. Use it to plan your project!

Product Features

Surface effects that stand out from the crowd.

The surface effects by SATTLER PRO-TEX allow both aesthetic and technical solutions that do not go unnoticed.

Surface sealing for strong and durable membranes.

The individual fields of application of our membranes place high demands on the surface protection among others. To ensure the highest performances, effective and long-lasting surface protection is needed.

Products which take responsibility for health and environment.

SATTLER PRO-TEX membranes comply with all safety and environmental standards across all fields of applications and beyond.

Use of light

A significant advantage of tensile fabric architecture lies in their lightweight and endless possibilities of shapes. This lightness is emphasized by the translucency of the membrane. For fabrics without a block-out layer, a certain amount of light is bound to shine through them – regardless of thickness and color. Translucent membranes can be used for architectural applications as a special design feature: the indoor environment is lit by natural light during the day, while artificial inner light creates special lighting effects on the outside of the building at night.

For information on the protection of your personal data, please refer to the