Best protection

Surface sealing for strong and durable membranes

Sealing the surface of a PVC-coated membrane fulfils several functions:

- It protects the underlying coating from harmful environmental influences and premature aging.

- It has a dirt-repellent effect and allows easy cleaning.

- It extends the durability of the fabric. It improves the weldability of the membrane.

- It increases the weld strength at high temperatures (70°C).

The applied lacquer determines the features of the finished product. Thus, the lacquer protects the PVC-coated fabric against weathering and UV radiation, and also simplifies cleaning.

In addition, SATTLER PRO-TEX membranes for architecture are protected from algae and mold by the latest generation of biocidal active substances and anti-fungicides.

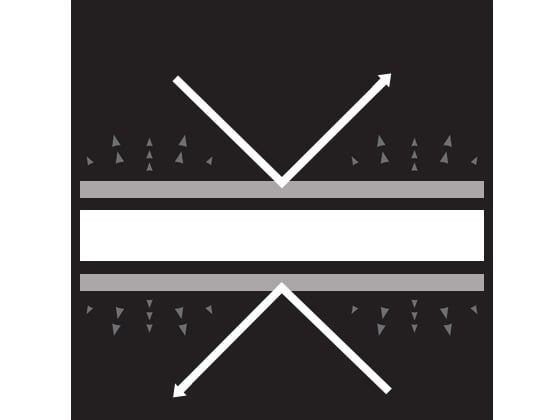

UV stabilizers and weather resistance

SATTLER PRO-TEX membranes for architecture have excellent weather resistance. In general, this is achieved during the manufacturing process through a stabilized PVC molecular structure, high-quality color pigments and UV light inhibitors.

Cold resistances of up to -45°C keep the fabric flexible also at low temperatures and facilitate the handling.

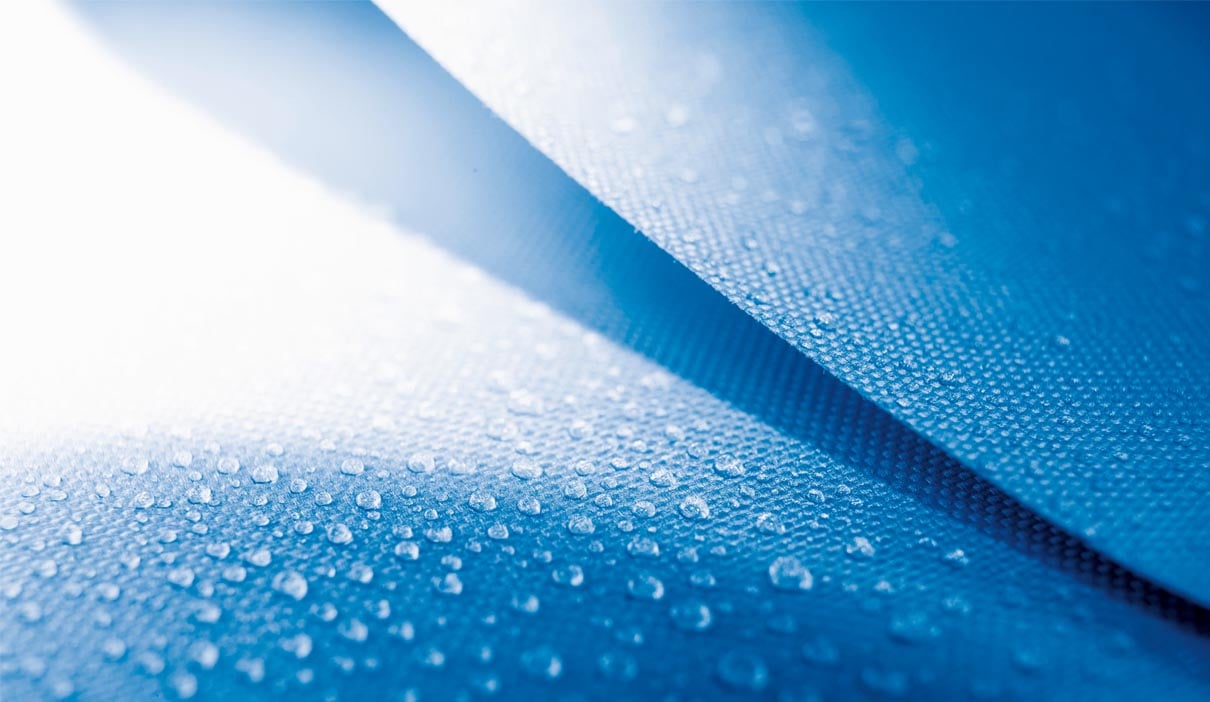

Anti-wick finish

The anti-wick system is a yarn treatment which prevents the penetration of microorganisms into the base fabric of the coated membrane. Treating the polyester multifilament base knitted fabric with a anti-wick finish prevents water from entering inside the fibers. Thanks to this water and dirt repellent treatment, it is possible to avoid negative influences on functionality and optics on the long term.

Our membranes for architecture and tensile construction are manufactured using woven anti-wick yarns.

Biocidal protection

Dirt and moisture are the breeding ground for the growth of microorganisms, and a biological presence on the surface causes an unpleasant look. The lacquered surface prevents adherence of soil and allows easy cleaning. This anti-microbial protection, combined with regular and professional cleaning, ensure a long lasting beautiful appearance. In addition, SATTLER PRO-TEX membranes for architecture are protected from algae and mold by the latest generation of active biocidal substances.

If microorganisms adhere despite the surface sealing, the anti-fungal finish prevents their growth and further spreading. All membranes by SATTLER PRO-TEX fulfill the requirements of the REACh regulation regarding all chemicals is use, and thus guarantee high functionality and safety of use at the same time.

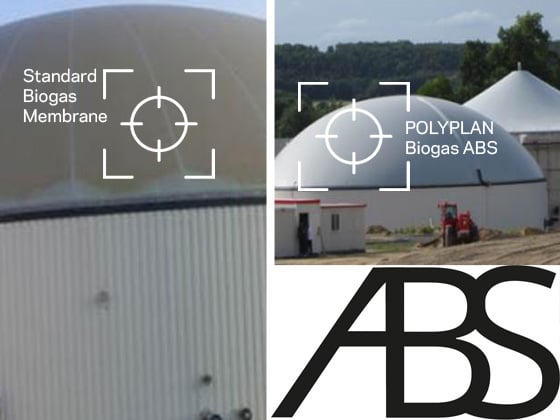

Anti-Browning-System (ABS) - Membrane with unique finish to counteract the „browning effect“

Discoloration of the outer membrane in biogas plants is not due to the aging of the fabric but to the composition of the substrate or the resulting biogas.

Depending on the dew points, organic substances condense on the inner side of the membrane and partly diffuse into the fabric. The following UV-induced oxidation reactions cause dark deposits. After years of field testing, we have succeeded in developing and offering our customers an effective solution that counteracts the discoloration of biogas membranes.

You may find this also interesting:

Surface effects that stand out from the crowd.

The surface effects by SATTLER PRO-TEX allow both aesthetic and technical solutions that do not go unnoticed.

Surface sealing for strong and durable membranes.

The individual fields of application of our membranes place high demands on the surface protection among others. To ensure the highest performances, effective and long-lasting surface protection is needed.

Products which take responsibility for health and environment.

SATTLER PRO-TEX membranes comply with all safety and environmental standards across all fields of applications and beyond.

Use of light

A significant advantage of tensile fabric architecture lies in their lightweight and endless possibilities of shapes. This lightness is emphasized by the translucency of the membrane. For fabrics without a block-out layer, a certain amount of light is bound to shine through them – re…

For information on the protection of your personal data, please refer to the